The IRT Division’s Supervisory Control and Data Acquisition (SCADA) System was comprised of twenty-six (26) power control zones operated via various different control systems (Series VII, OASYS, DYNAC OS, and DYNAC ES). A majority of the zones were the older Series VII, OASYS systems that were installed more than 30 years ago and were beyond their life expectancies. The IRT Series VII data acquisition system was the first generation of acquisition system based on Logic control. This system provided basic information and control of rectifiers, breakers, entry doors, battery charger, rail alive, and associated devices. The Master Terminal Units (“MTU”) at the Power Control Center (PCC) were circa 1980 computing units that were cumbersome to use, expensive to maintain, and technologically obsolete. As a subconsultant, SI Engineering, P.C. (SIE) provided scope development services for this design-build project, which aimed to upgrade the IRT division SCADA system to DYNAC ES version 15 or later SCADA system and provide backup at the Emergency Power Control Center (EPCC).

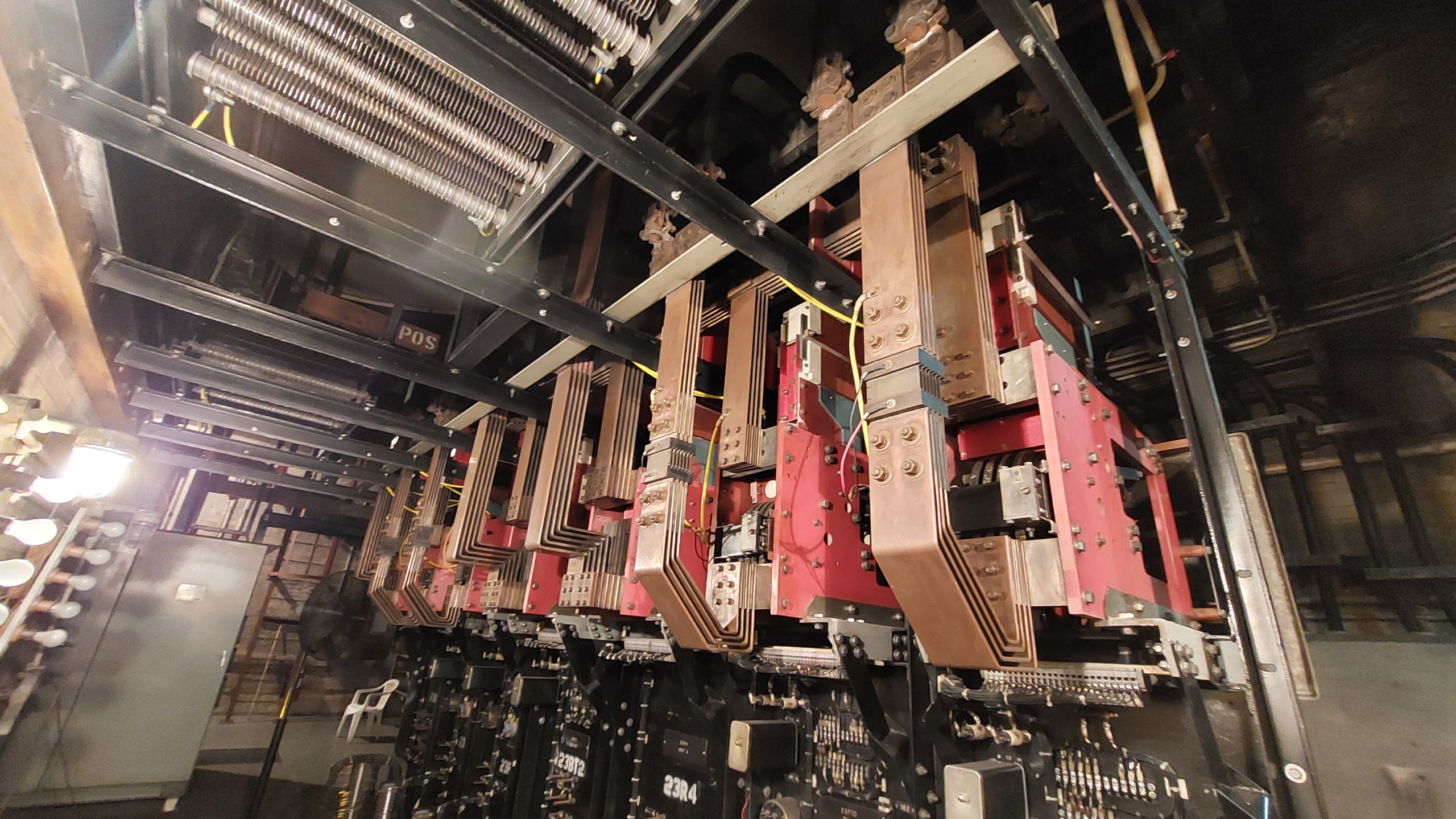

The project scope included upgrading outdated IRT Division Master Terminal Units (MTU) at the PCC with a new LCD video wall system that will display mimic track graphics, control and indication graphics, and other essential data. This included the System Operator and District Operator consoles and workstations, along with the renovation of the PCC Theater space to better house the new equipment. The scope also included evaluation of the existing IRT server and HVAC systems in the PCC SCADA Server Room and upgrading the systems as needed. The project also included an assessment of the power backup capabilities for critical workstations in the PCC SCADA theater and network operations theater and providing connection to uninterruptible power supplies (UPS) and generator backup power as needed. The project also involved furnishing and installing a PLC-based SCADA system with a Main PLC, Distributed Input / Output cabinets, and local operator interfaces at each IRT Zone Control Substation, including fiber-optic to connect substation control rooms to nearby passenger station communication rooms for redundant network connections, enabling information transmission between control zones and the PCC. New LCD monitors, video wall system and workstations, a new PLC-based SCADA system, and a new telephone system for operators’ communication between the PCC, ZCRs, and EPCC were also provided under this contract.

As part of the scope development task, SIE was responsible for gathering and reviewing existing documents for PCC, EPCC, and 26 IRT Zone control rooms and associated communications rooms. SIE performed field surveys to document existing conditions and evaluated the PCC power system and air conditioning to support SCADA upgrades. The project scope also included the installation of a new IRT AC distribution panel, assessing PCC Power backup capability for the SCADA Theater and PCC 1st Floor Operations Theater, and evaluating power requirements at the 26 IRT ZCR and EPCC to accommodate new SCADA equipment. SIE estimated the existing cooling capacity of equipment, heating load generated by the equipment in the space, and proposed possible solutions to eliminate the cooling shortfall in the space. All information gathered was incorporated into the Master Plan and Base Line documents.